Geka News

Manufacturing with steel had its origin around 2000 BC in India and China. In less than 1000 years, in 1200 BC, the iron age started and with it the popularity of designing metals started spreading through the whole world. Since then, the technology used for manufacturing steel has developed exponentially and it continues to develop. This is exemplified by all the latest advancements in CNC processing and punching tools. By reading our Geka news page, you can follow the latest trends and developments in steel processing, designing and manufacturing.

Geka news: keeping track of the steel processing industry

Keeping up with our Geka news content is a great way of keeping track of everything that is going on in hydraulic manufacturing and to learn about the innovation and technology surrounding the steel and metalworking industries.

Having the latest information will also help you to learn reliably about the different steel manufacturing machinery and which one best suits your particular needs. Reading the Geka news page, you will also be able to gain knowledge about how to use our products and all the functionalities that are included with them. Also, you will learn about all the new products that we launch.

Steel and metal manufacturing continues to be an essential industry in the United States and around the world. Some important data points about the iron & steel manufacturing industry in the United States this year:

- $103 billion market size

- 412 businesses

- 80,828 employees throughout the whole industry

We have more data points like these waiting for you in our Geka news content. Would you like to keep reading statistics and information regarding the state of the iron and steel manufacturing industries? Keep up with our news content.

Follow Geka news if you want to keep track of how the different metal working manufacturing processes and technology continue to constantly evolve.

GEKA CNC Machine Showroom in Aberdeen, Maryland!

We are excited to announce the upcoming opening of our brand-new GEKA CNC Machine Showroom in Aberdeen, Maryland! This milestone reflects our commitment to delivering high-quality industrial machining solutions, featuring CNC machines for steel punching, shearing, and...

Join Us at INTEC 2025 in Germany: The Leading Machine Tool Trade Fair

We’re excited to announce that GEKA will be attending INTEC 2025, one of the most important machine tool trade fairs in Germany! 🇩🇪 From March 11th to 14th, we’ll be at Hall 2, Booth K29, alongside our distributor @joas_werkzeugmaschinen, showcasing our advanced...

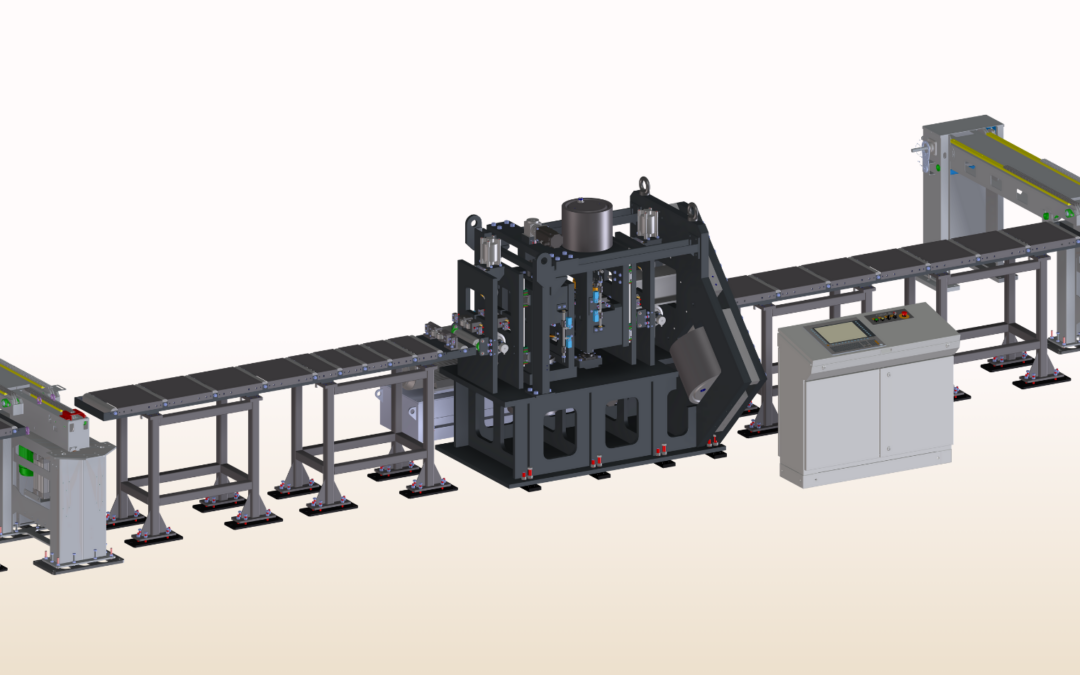

GR BEAM: The Automatic Solution for Beam Punching and Shearing

The GR BEAM Automatic Line is set to revolutionize beam processing in the solar pile industry. This advanced machine delivers high precision, reduced manufacturing times, and an optimized workflow, making it an ideal solution for fabricators looking to enhance their...

GEKA Strengthens Its Presence in the Solar Industry!

At GEKA, we are proud to announce the installation of two more PUMA 2HI machines in the USA for Solar Pile Processing. This installation is part of an exciting five-machine project that also includes our GR BEAM, an Automatic Line for Beam Processing set to be...

The Manual Solution for Punching and Shearing Beams for Solar Trackers: PUMA 2HI + SHEAR MASTER

When it comes to processing beams for solar trackers, efficiency and precision are key. That’s why the PUMA 2HI and SHEAR MASTER for BEAMS are the perfect combination for fast, efficient, and waste-free production. These beam processing machines are designed to meet...

PUMA 2HI: The Solution for Beam Punching

The Fastest and Most Efficient Solution for Beam Punching, Ideal for Solar Trackers. The PUMA 2HI is designed to revolutionize W6 and W8 beam punching, offering unmatched efficiency and precision. With the ability to deliver two, four, or six punches per stroke, this...

We’ve confirmed some of the trade shows we’ll be attending in 2025!

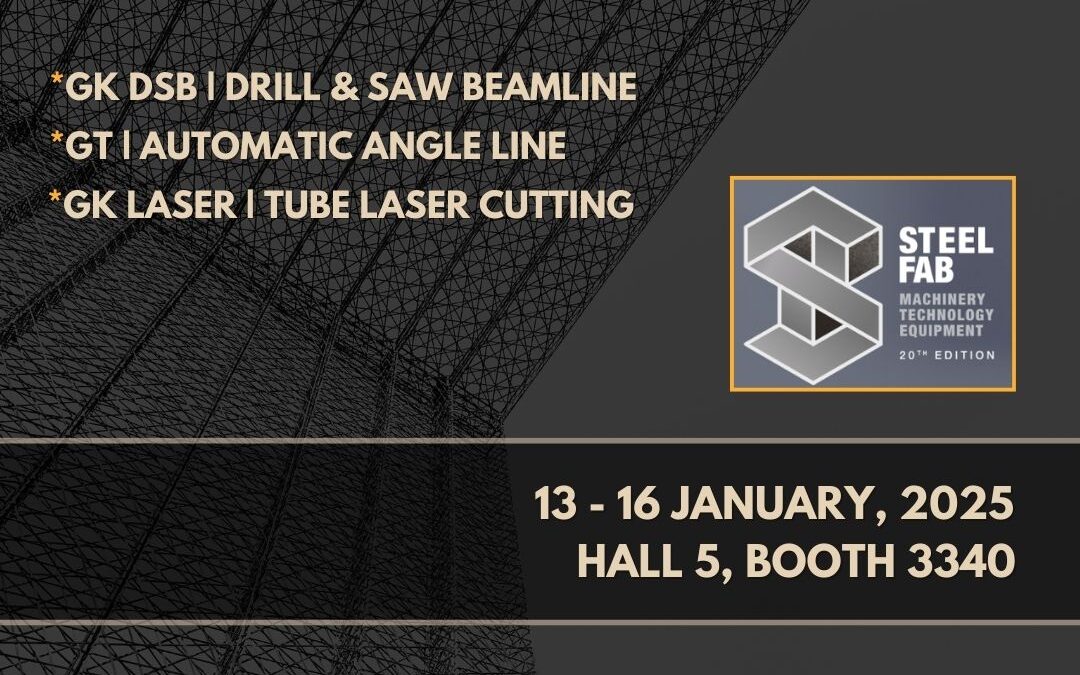

In 2025, we will be participating in several key trade shows for the metal sector, machinery, and structure manufacturing. Below are the confirmed dates and details of these events: SteelFab in the UAE: January 13–16, Hall 5, Stand 3340SteelFab is one of the leading...

GEKA in ISMR: Innovation and Trends in the Metal Industry

We’re featured in ISMR magazine! 🎉 In their October edition, we had the opportunity to share our strategic vision and the latest developments in metal processing machinery with this prestigious publication. Here’s a brief summary of the key topics covered in the...

We’re Kicking Off the 2025 Trade Show Season at SteelFab

As the new year begins, we’re excited to announce our participation in SteelFab 2025, one of the most prominent trade shows for the metal fabrication and steel industry. From January 13 to 16, you’ll find us at the Expo Centre Sharjah, showcasing our latest...

Mactech Exhibition 2024!

From December 12th to 15th, we had the pleasure of participating in Mactech Exhibition 2024 in Cairo alongside our dealer, Comex KSA. This event was an incredible opportunity to showcase our most advanced solutions in steel shearing, punching, bending,...