Geka Ironworkers, Punching Machines & CNC Lines / Solutions

We manufacture hydraulic ironworkers, CNC lines and more ironworking equipment and parts. Our products are precise, durable, reliable, and customizable to your specific manufacturing needs.

Geka has been a steel working machine manufacturer since 1919.

Hydraulic Ironworkers, Consumables and CNC Lines & Solutions.

Geka USA offers the reliability that comes with our more than 100 years of experience in innovating, designing and manufacturing hydraulic ironworkers and CNC lines and solutions.

The Geka Group has had a long history as pioneers developing machines and bringing unique solutions through our experience in the steel working industry. The products and machines available from Geka USA feature ironworker machines—including some punching machine options—and CNC lines. Through our technical service, we may also provide our clients with customizable solutions and replacement parts for their ironworking process.

Hydraulic Ironworkers

Geka USA features strong, versatile and reliable hydraulic ironworkers for punching, notching, cutting and bending profiles, steel plates, angles and bars.

Accessories

Geka USA can provide customers with accessories for punching, notching, bending and cutting or other specific jobs.

We offer a wide range of GEKA USA original accessories.

CNC Lines and Solutions

CNC Lines and Solutions for working angles, flat bars, plates and beams. Optimize your processes with our CNC Solutions.

Consumables

Punches, dies and blades for GEKA Hydraulic Ironworkers and CNC Lines.

Our selection of punches, dies and parts.

Our Geka news page features up-to-date content about innovation, trends, news, and everything you need to know about steel processing technology.

Subscribe to our newsletter and stay up to date.

We purchased the first alpha 500 in the US market almost 20 years ago to aid in our growth and to assist us in our plate and angle processing and with the on going support from our friends at GEKA this unit is still producing.

Many thanks to the employees of GEKA for being a strong partner of BWS Industries Inc.

Michael Archer / President

BWS Industries Inc.

I contacted GEKA, for a very specific part that I was unable to find anywhere. A part that is used on their IronWorker. They responded in a timely manner and were very helpful in finding exactly what I needed. I was amazed with the efficiency of GEKA’s parts department as they placed my order and sent it my way.

Jake Fehr

MAXX-D Trailers

Copper Processing

The GEKA Minicrop is a great machine in use every day for Copper Processing.

The cropper has been a great asset to our business.

I am definitely working with GEKA again, knowing I am in good hands.

Barry Smith (Director)

BATES Mining Specialists

Services for your GEKA machine.

Choose below the service you want to contact with.

Sales Consultant

Ask our experienced sales consultants to provide you with extensive information and advice.

Brochure Request

You can ask for any brochure or information about any of our products.

Technical Support

After sales assistance by GEKA’s qualified engineers.

Manuals Request

You can request here any manual for your machine or GEKA original tools.

Our Hydraulic Ironworkers and CNC Lines are designed by technical experts, following the experiences and suggestions of thousands of final users. Our high-quality standards, far superior to those of other ironworking machines on the market, allow us to manufacture technically superior machines of excellent quality.

GEKA News.

Why Is Automation Transforming Structural Steel Processing?

In recent years, automation has gone from being a futuristic option to becoming a real necessity across many industrial sectors. One of the most significantly impacted areas is structural steel processing — especially in operations like punching and shearing metal...

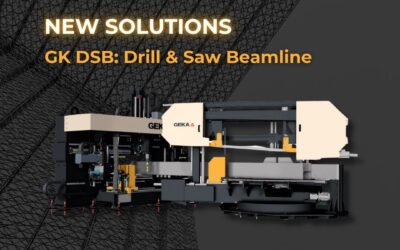

DSB – Beam Drilling and Sawing Line

In the industrial sector, optimizing production time without compromising precision is key. That’s why at GEKAUS, we have developed the DSB, a compact CNC line that combines high-speed drilling with automatic band saw cutting, including automatic mitre cuts from +45º...

GK DSB Drill-Saw Beamline

GK DSB Drill-Saw Beamline: Precision and Efficiency in Beam Processing At GEKA, we continue to innovate in steel processing solutions, and the GK DSB Drill-Saw Beamline is our latest advancement. This fully automated beam processing line delivers unmatched performance...