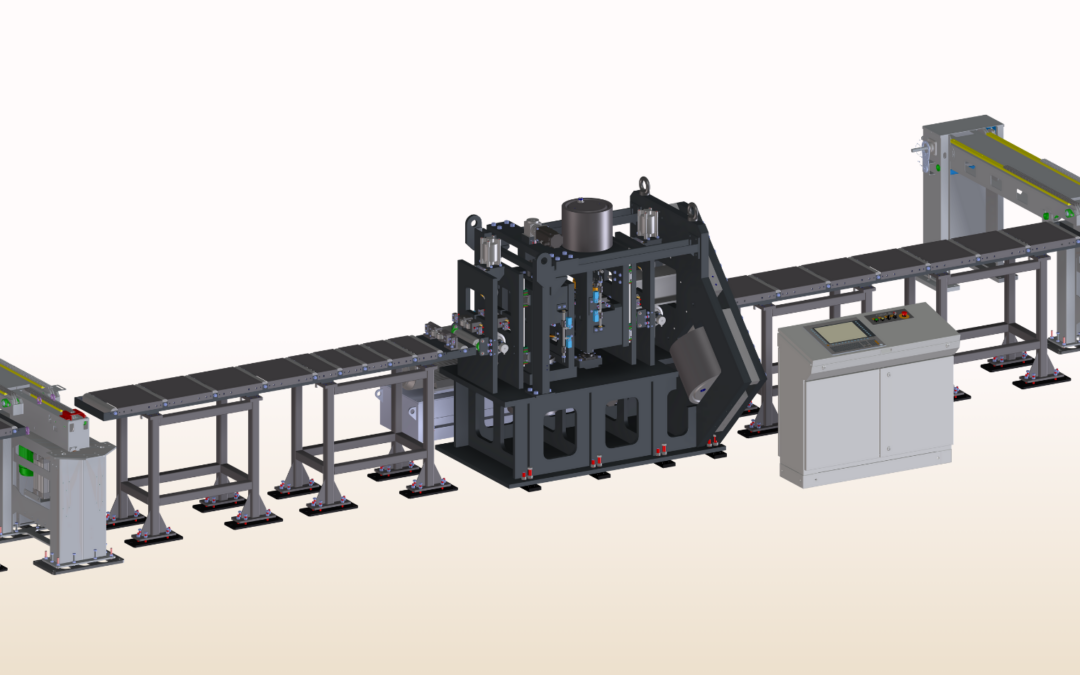

The GR BEAM Automatic Line is set to revolutionize beam processing in the solar pile industry. This advanced machine delivers high precision, reduced manufacturing times, and an optimized workflow, making it an ideal solution for fabricators looking to enhance their production capabilities.

What makes GR BEAM stand out?

🔹 High-Efficiency Punching

- Equipped with two punching units, the GR BEAM can execute two, four, or six punches in a single stroke, significantly increasing productivity.

- It can punch up to six holes per flange, making it an ideal solution for solar piles and structural beams.

🔹 Fast and Precise Shearing

- The machine is capable of shearing a W8x40 beam in just 7 seconds, drastically reducing processing time.

🔹 Fully Automatic Operation

- Features an automatic loader and outfeed, ensuring a seamless workflow and maximizing efficiency in beam processing.

Installation in Texas – A Competitive Advantage for Solar Pile Manufacturers

This June, we are installing the GR BEAM in a customer’s facility in Texas, giving them a huge competitive advantage in the solar pile industry. With the ability to punch multiple holes per stroke and shear beams in seconds, this machine will increase production speed, reduce labor costs, and enhance overall efficiency.

The Future of Beam Processing

The GR BEAM Automatic Line is not just an upgrade—it’s a breakthrough in beam punching and shearing technology. For solar pile manufacturers, steel fabricators, and structural beam processors, this innovation ensures higher productivity, greater precision, and reduced material waste.

Would you like to optimize beam processing and make your production more efficient? Contact us and discover how the GR BEAM can help you improve your results. sales@gekaus.com

🔎 Also, check out our manual punching solutions for solar trackers and find the perfect fit for your production needs!