NEW GEKA USA Punching Capacities Calculator

Perimeter(p) x Thickness x Tensile/2000 = US Tons

Please refer to the below drawing for more information about how to calculate the perimeter (p) of the most common shapes.

CAUTION: Never punch a diameter

smaller than the material thickness

Please select a shape and introduce measures:

Fill in two of the three first fields and get the result for the missing

field.

Resistance is a compulsory field.

Example: for a given diameter, thickness and strength*, work out the tonnage.

Resistance is a compulsory field.

Example: for a given diameter, thickness and strength*, work out the tonnage.

Usual material strengths

DISCLAIMER

| Material Name | Minimum Tensile | Maximum Tensile |

|---|---|---|

| A36 | 58000 | 79800 |

| 1018 | 64000 | |

| 304 | 73200 | |

| 304 | 73200 | |

| 316 | 84100 | |

| 316L | 81200 | |

| 6061 T6 Aluminum | 45000 | |

| Copper | 35000 |

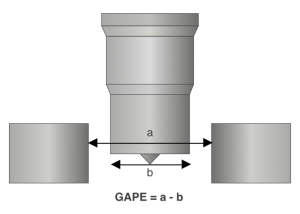

Nevertheless, it is very important to apply

the correct gap between punch and die:

the correct gap between punch and die:

| THICKNESS | RECOMMENDED DIE CLEARANCE |

|---|---|

| 1/8″ to 1/2″ | 1/32″ |

| 1/2″ to 3/4″ | 1/16″ |

| Mild steel (ST37 to 42) | 10 % |

| 3/4″ to 1″ | 3/32″ |

| 1″ & + | 1/8″ |

Do you need help with your GEKA Ironworker?

Choose below the service you want to contact with.

Sales Consultant

Ask our experienced sales consultants to provide you extensive information and advice.

Brochure Request

You can ask for any brochure or information about any of our products.

Technical Support

After sales assistance by GEKA’s qualified engineers.

Manuals Request

You can request here any manual for your machine or GEKA original tools.